The perils of corporatization

January 3, 2018 | Expert Insights

Toray Industries Inc, a Japanese multinational corporation has admitted to having falsified data. The company has said that there were 149 cases of data falsification that had taken place over the period of eight years.

In 2017, a number of Japanese companies have been embroiled in controversies regarding cheating. Is this the end of Japan Inc?

Background

The quality movement in Japan began in 1946 with the U.S. Occupation Force's mission to revive and restructure Japan's communications equipment industry. In 1950, W. Edwards Deming gave a seminar in Japan on statistical quality control (SQC). In the span of 10 years Japan trained nearly 20,000 engineers in SQC methods, taught methods for statistical analysis and control of quality to Japanese engineers and executives. This can be considered the origin of TQM.

Some of the quality methods employed by Japanese companies are Just in Times, TQM, Kaizen and S5.

Suzuki Shoten was a conglomerate which existed in Japan in and around 1900. In 1905, Suzuki Shoten bought Kobayashi Steel, and it became Kobe Steel. Headquartered in Chūō-ku, Kobe, it is the third largest steelmaker in Japan. Nippon Steel & Sumitomo Metal is the largest steelmaker in Japan and second largest in the world in terms of volume. Toyota, Nissan, Boeing are among the companies that use the products from Kobe Steel.

Japan over the years has prided itself on its reputation for quality manufacturing. It has used this as a selling point over China and other countries that offer cheaper alternatives to goods. The Japan Quality Association (JQA) is responsible for ISO certification. It was established in 1958 as the Japan Management Institute (JMI) under Japan's Ministry of International Trade and Industry for the purpose of export inspection.

Toray Industries

Toray Industries, Inc. is a multinational corporation headquartered in Japan that specializes in industrial products centered on technologies in organic synthetic chemistry, polymer chemistry, and biochemistry.

Analysis

In 2017, some of the biggest Japanese countries upon whom the country’s reputation was built on, admitted to cheating and falsifying data. One of the largest scandals was the Takata Corporation admitting to having covered up facts. The company’s airbags were directly linked to a number of deaths and injuries that had occurred across the world. This resulted in legal action against Takata. In 2017, Takata filed for bankruptcy protection in the US and Japan. It is facing billions of dollars in liabilities over its airbags.

In August 2017, it was reported that Mitsubishi Motors missed employee warnings about widespread cheating on fuel economy data over 25 years. An independent report verified these claims over the Japanese carmaker’s governance failures.

Additionally, Suzuki Motor admitted that the company had been exaggerating the fuel economy of its vehicles by cheating on tests. Nissan announced the recall of 1.21 million vehicles in Japan after it was revealed that unauthorized technicians were carrying out checks.

In October 2017, Kobe Steel revealed that it had falsified data that resulted in affected 19,300 tons of flat-rolled and extruded aluminum products, 19,400 units of aluminum casting and forgings, and 2,200 tons of copper products. This amounts to 4% of Kobe’s output from September 2016 to August 2017.

Toray Industries Inc, a Japanese multinational corporation has now admitted to having falsified data. The company has said that there were 149 cases of data falsification that had taken place over the period of eight years.

The firm said the cheating involved tyre-strengthening cord that was sold to 13 clients by Toray Hybrid Cord. Toray said its subsidiary became aware of the problem in July last year, and the group was informed in October. It publicly disclosed the situation after rumors appeared recently in an anonymous online post.

“There were no legal violations or safety problems; this was between us and our customers, and so there was no need to disclose it,” Toray President Akihiro Nikkaku told a news conference.

A report by outside experts point to lack in labor resources and lax management as main culprits for the problem. There was also alleged pressure on employees to meet delivery dates despite limited manpower and poor work conditions caused by deteriorated measuring equipment.

Assessment

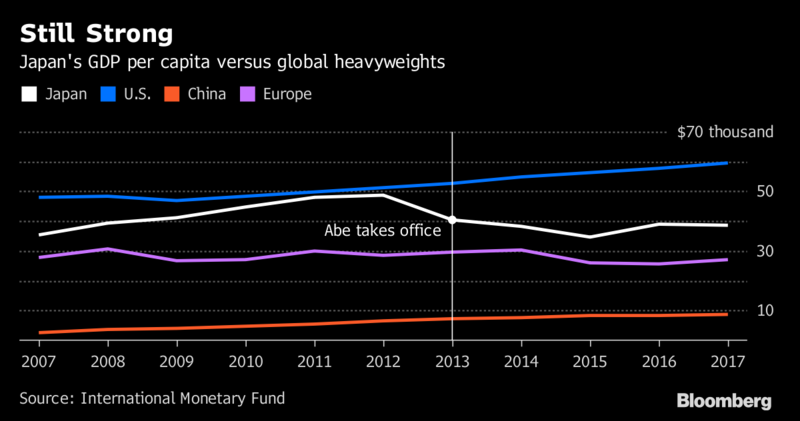

Our assessment the multiple scandals have dented the trust international community has on the Japanese manufacturing industry. This signals a problem as the nation’s economy was built on its manufacturing sector. Perhaps there is a lesson here not only for Japan but also nations like India about the problems that come with corporatizing a nation. Countries cannot be run as companies and there are pitfalls inherent in the practices of optimization.

Comments